Installed & initial impressions!

Alright I've completed my install and nearly put a full tank of gas through her! Here's the write up and initial impressions.

Installation

Unboxing. Everything was nicely packaged.

Here's the contents of the 40' inline pump kit. They accidentally gave me an extra bulkhead fitting for the gas tank return. Only 1 is needed.

The contents of the throttle body kit. All the components have a very high quality feel to them. The wiring harnesses and connectors are nicely made. The supplied 02 & coolant sensors are top notch.

After removing all my old carburetor components, the first task was to install a tank bulkhead fitting into the gas tank. This is required for the return line.

Don't be afraid about doing this task on your own with the aid of a helper; if you take your time and do things right you'll do just fine. The best location to me appeared to be in the ~11 o'clock position. Using a 9/16 bit, mark where your hole is going to go. Then, with a helper, flip the tank upside down and drill the hole upside down while your helper runs a vacuum to suck all the filings as you drill. In this way you minimize any chips that need to be cleaned out. It is also important to have a dry tank when you do this as not to cause any pieces of metal to stick to the inside of the tank.

Debur the hole after drilling, inside and out.

Install the 90 deg. bulkhead fitting using the sealing washers supplied. This is the tricky part. I used a 1/4" drive ratchet with a deep well socket to install the nut from the inside of the tank. Use electrical tape, and or zip ties around the ratchet handle and socket cylinder to manipulate the ratchet into place. If you have a sacrificial box-end wrench it may be easiest to put a 90 deg bend in it so you don't have to use a ratchet.

Attach the 'fuel cuff' to the threaded end of the bulkhead fitting inside the tank. This is a bit easier to do with a simple box end wrench.

Boom, tank is ready to go.

Next, you really need to put some time and effort into thinking out your wiring depending on your level of OCD & 'accessories' that you are trying to run. I am NOT using timing control.

I highly recommend using the supplied fuel pump relay circuit.

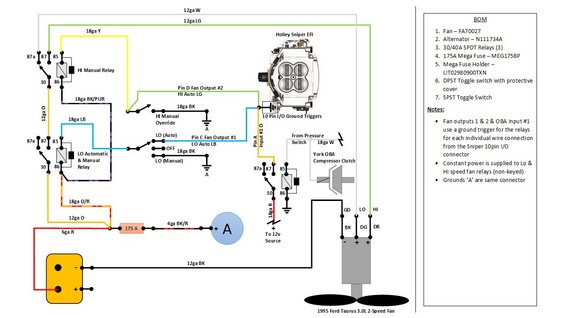

I am running a 2-speed Ford Taurus fan setup.

Here's my schematic:

https://drive.google.com/open?id=0BwP3o_tmutwxOVJkQndaQTZXcVU

This setup is somewhat complex overall, but it really integrates nicely into the Holley Sniper system capabilities using it's optional relay ground triggers. It gives me the benefit of the first fan speed turning on at 190, and the second 'Hi' fan speed turning on at 200. Or I can configure those temperature to whatever I want them to be. My above setup also gives me the ability to manually override the system by turning the fan off, or on at any time for any reason. Here are my KC lights, fan, and fuel pump relays & fuses.

Some additional wiring that I hooked up was another ground trigger for the "A/C Kick" functionality of the Sniper system. Basically, when the A/C compressor kicks on, the ECU gives the rpms a little boost to compensate for the extra load on the engine at low idle. I am using the A/C compressor for my OBA system, not A/C, fyi. Here's the A/C compressor kick relay + manual reverse light relay.

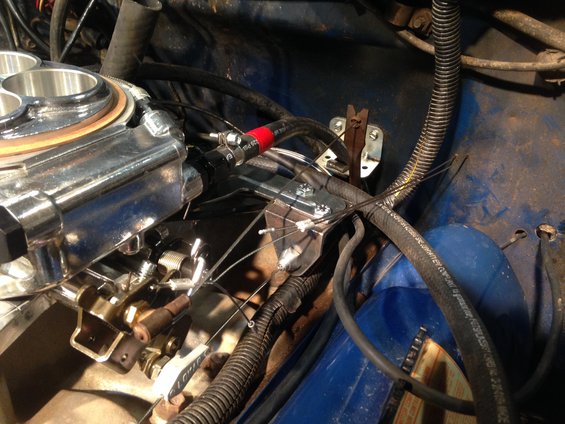

One thing that I did not care for was the fact that all the wiring harnesses connect to the Sniper throttle body unit via ~12" pigtails from the throttle body. This means your harness connectors are in awkward places throughout the engine compartment. What I would prefer is that the connectors are actually on the throttle body itself, so that all the connectors are 'attached' at the throttle body. This would also be a major benefit if the unit needs to be removed for any reason. The way it is now, I would have to cut zip ties, and spend some effort just to unwire the throttle body to remove it.

In this picture you can see the connector just sitting on top of the heater box.

For your 12v constant on power to the pink ECU wire, use the little blue wire in the 2pin connector at the firewall near the heater box. For me, this wire was previously used for electric choke.

Here's my 02 sensor. I run fenderwell exit Hedman headers.

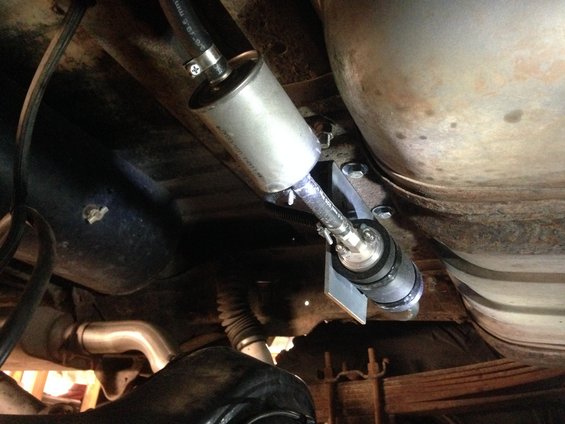

Next is the fuel pump. For the inline fuel pump, you will need to make a custom bracket to get as close to the bottom of the tank as possible. This was fairly easy. Piece of scrap metal I had lying around:

Red is high pressure feed, blue is low pressure return.

It does kinda feel like the pump is hanging 'down out in the open', because it is. However, it's shielded pretty well by my plate and it's out of the danger zone of my differential and any obstacles I might be going over. The ports of the pump are at the lowest level of the tank. Should make it pretty easy to wash off lol.

Once you've run your fuel lines, it's time to hook up throttle cables and transmission kickdown cables. You NEED to convert to the Lokar cable kickdown kit, per the recommendation of Holley:

Holley DOES NOT produce any kickdown lever/cable solutions whatsoever for the Sniper + C6 combination. The Holley rep could not tell me if they plan to offer one in the future. The Holley rep recommended Lokar to supply the solution.

To install, it's pretty straightforward but does require a little custom bracket making. Take the included kickdown cable bracket intended for other transmissions:

And cut off the vertical portion. It is not needed and gets in the way.

Take a piece of 2" angle iron, cut to size, and drill some holes.

After I hooked up my pedal throttle, hand throttle, and cruise control:

Here's a transmission end of the kickdown cable:

In this picture you can see the 02 sensor connector on the right hand side

A note on running fuel lines up to the throttle body. I had a fuel regulator mounted on the firewall. I used its bracket to run my high pressure hose through. This way it's kept in the center of the back of the transmission. I zip tied my supply and return lines together.

A look at the finished installed product. Pretty sexy!

How does it perform?

Setup was very simple and straightforward following the supplied quickstart guide. I calculated my displacement to be 414.xx cu in. at 0.060 overbore.

I used the 'stock cam' setting even with a 'mild' Comp Cams cam.

After following all the recommended procedures, the engine literally 'jumped' to life with 1/2 a crank! It literally surprised me and caught me off guard.

Immediately I noticed my idle quality was much smoother. I followed the recommended initial start and idle setting procedures and all was well. I targeted an idle of 750 rpm initially.

I went for a test drive and boy I was impressed. I could tell there were a few lean spots on hard acceleration, but after a thorough amount of driving those have all gone away with the self learning.

I have spent the most time tweaking the advanced idle parameters. I was unhappy with how long the engine remained at an elevated rpm after initial startup. I was impressed to find that all of these times and rpms are tunable via the hand held.

The hand held is nice, albeit a little small.

I really wish it came with a windshield mount. It comes with a protective cover/stick-on mount but it requires a flat surface. I will have to investigate a better long-term mounting solution. The unit also comes with a stylus, this is particularly useful to tune the idle curves that have small points on a graph that are too difficult to move with a fat finger.

I can't say enough about the noise level of the fuel pump. It is virtually non-existant! My old pump was soooooo loud, this thing is silent! Other than a brief prime, you wouldn't even know it's there. I can't say enough how happy I am with this characteristic.

Since I don't even have a full tank of gas through it yet, I cannot comment on gas mileage; and since my tires are 35" and my gearing is off I will have to use a gps to track my mileage. But eventually, I will get it. The problem is, I don't have a comparison to the carburetor because I never tracked it before. Fuel mileage gains were NOT why I went to fuel injection.

Power definitely seems increased (or at lease optimized) and much more consistent. I did the easiest burnout (and most expensive!) burnout I've ever done! The amount of low-end torque is really incredible. Finally, the throttle response is fantastic.

All-in-all, Holley hit a home-run with the Sniper :thumbup I have already benefitted from their fantastic phone support as well, which is one of the reasons I chose Holley over FiTech.