PLEASE READ THIS ENTIRE POST BEFORE ASKING QUESTIONS!!!

Had to start this thread since there is much misinformation and confusion about the 3G alternator upgrade. This is not an install thread, just a guide on where to get the alt you need, a wiring diagram, and pulley sizing. Most photos and some of the text is courtesy of Ryan McCormick of FordFuelInjection.com. Hope he's well, wherever he is.

Why go 3G?

Because your factory alternator is barely adequate for your truck, stock.

Added off-road lights or a big stereo?

You need a bigger alternator!

Need me to show you?

![Image]()

And that's alternator RPM, not engine rpm. The alt spins much faster than the engine.

Alt RPM = Engine RPM x Crank Pulley Diameter ÷ Alt Pulley Diameter.

87-92 is the blue line.

93-96 is the green line.

78-86 is less than the blue line.

There are 3 different mounting styles for the 3G alternator that can be used as an upgrade on other vehicles:

If you have a 66-86, anything with v-belts, or a 87-98 300 (4.9L) or 460 (7.5L): you'll need a Pivot Mount w/ 8.25” ear spacing alternator. Order an alt for a 93-96 E150 with a 4.9 and the High Output or Rear A/C option. On your v-belt truck, you may also be able to use one that fits the 87-92 serpentine setup (Pivot Mount w/ 7.00” ear spacing) but some may have fitment issues with smog pump location. The Pivot Mount w/ 8.25” ear spacing can be swapped into:

1966-1986 V-belt Mustangs

1966-1987 V-Belt Broncos/E-Series/F-series

1992-1997 4.9L & 7.5L Bronco/F-Series/E-Series

Other V-belt vehicles that can adjust to an 8.25” wide Pivot mount alternator

A wide-eared Taurus alt will ONLY fit a 302 or 351W if it is a V-belt setup since it's wider than a serpentine one.

![Image]()

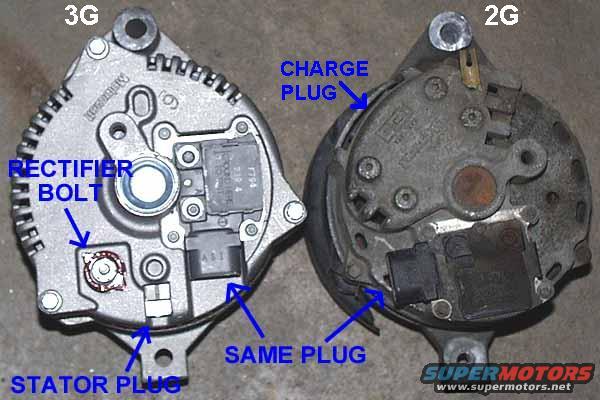

If you have an 87-92 302 (5.0L) or 351W (5.8L): you have a 2G alternator.

![Image]()

![Image]()

This is an early serpentine style. This can only be replaced with a Pivot Mount w/ 7.00” ear spacing alternator. Minor bracket clearancing will be required.

![Image]()

![Image]()

This can be found in the following cars:

93-99 narrow-eared non-DOHC Taurus

94-95 V8 Mustang

94-00 V6 Mustang

94-97 V6 T-Bird/Cougar

95-98 Windstar

91-94 V6 Lincoln Continental.

The early serpentine car and truck alts on Ryan's site are interchangable but the plug and charge stud are clocked differently to fit the wiring to the bracket better. The Pivot Mount w/ 7.00” ear spacing can be swapped into:

1987-1992 Broncos/E-Series/F-series

1966-1995 Mustangs

Other vehicles that use a 7.00” wide Pivot mount alternator

If you have a 93-96 302 (5.0L) or 351W (5.8L): you have a Side Mount 3G already but a 95 amp one. You DO NOT need to get a wiring harness, as since you already have a 3G, it's plug and play!!! I strongly urge you to get a larger charge cable and megafuse though.

For a 130 amp, you can get that for a:

93-96 V8 Econoline with Rear Air Conditioning or the High Output Alternator options

97-03 V6 Econoline E-Series or F-150

95-01 4.0 V6 Explorer or Ranger

at your local parts house for less than eBay.

You'll need the one for late serp. vehicles.

The Side Mount can be swapped into:

1993-1997 5.0L, 5.8L & 7.5L Bronco/F-Series/E-Series

Other vehicles that use a Side Mount alternator

Or you could try to find one like that at a junkyard.

![Image]()

![Image]()

![Image]()

A Note On Belt Squeal: Some 3G alternators create an extra large load on the belt upon engine startup. There is a later part number soft-start regulator that you can be on the look out for. Read more about this here. Thanks to Fodder, SRWillis, and silver70 for the heads up.

Plug Clocking: Each style may have the rear plugs clocked 3 different ways to fit their various vehicles better. They will still fit no matter the clocking but you can remove the case bolts, and reclock the rear to get your optimum position.

Wiring Harness and Charge Cables: The wiring is very simple. I prefer to grab the harness off of certain donor vehicles and then modifying them if they are in great condition. 94-95 Mustang GT's are my favorite as the charge cable is a great length. Many harnesses are available online if you can't find one that suits your needs.

![Image]()

When you swap to a 130 or higher amp 3G, although you do not NEED a larger charge cable such as a 2 Gauge, it is a great idea. Smaller wires/cables cannot always handle such a load and they tend to heat up, some to the point of melting the wire and could start a fire. ALWAYS make sure you use a megafuse rated at least 15-25 amps above your alternator amperage.

Pulleys: For pulleys, you can either re-use your old one, which sometimes you may need a very small washer to use as a spacer if it rubs in the 3G case at all, or you can get a different sized one. It all depends on your needs. A smaller pulley will spin the alternator faster at idle to create maximum output. A larger pulley will allow the engine to rev higher without driving the alternator to fast. Large 3G alternators are safe to ~15,000RPM max. Again, Alt RPM = Engine RPM x Crank Pulley Diameter ÷ Alt Pulley Diameter.

Factory Carb Users: If you have a Factory Ford carburetor (Holley model 4180) with a wire that connects directly to your 1G alt to your electric choke, get a 12 volt electric choke for a Holley 4160, P/N 45-223, and swap it out. Then wire the new choke to 12 volts with key on.

This post will continually be edited as information pops up. Please post any errors you find so this can be THE thread for 3G interchange information.

Had to start this thread since there is much misinformation and confusion about the 3G alternator upgrade. This is not an install thread, just a guide on where to get the alt you need, a wiring diagram, and pulley sizing. Most photos and some of the text is courtesy of Ryan McCormick of FordFuelInjection.com. Hope he's well, wherever he is.

Why go 3G?

Because your factory alternator is barely adequate for your truck, stock.

Added off-road lights or a big stereo?

You need a bigger alternator!

Need me to show you?

And that's alternator RPM, not engine rpm. The alt spins much faster than the engine.

Alt RPM = Engine RPM x Crank Pulley Diameter ÷ Alt Pulley Diameter.

87-92 is the blue line.

93-96 is the green line.

78-86 is less than the blue line.

There are 3 different mounting styles for the 3G alternator that can be used as an upgrade on other vehicles:

If you have a 66-86, anything with v-belts, or a 87-98 300 (4.9L) or 460 (7.5L): you'll need a Pivot Mount w/ 8.25” ear spacing alternator. Order an alt for a 93-96 E150 with a 4.9 and the High Output or Rear A/C option. On your v-belt truck, you may also be able to use one that fits the 87-92 serpentine setup (Pivot Mount w/ 7.00” ear spacing) but some may have fitment issues with smog pump location. The Pivot Mount w/ 8.25” ear spacing can be swapped into:

1966-1986 V-belt Mustangs

1966-1987 V-Belt Broncos/E-Series/F-series

1992-1997 4.9L & 7.5L Bronco/F-Series/E-Series

Other V-belt vehicles that can adjust to an 8.25” wide Pivot mount alternator

A wide-eared Taurus alt will ONLY fit a 302 or 351W if it is a V-belt setup since it's wider than a serpentine one.

If you have an 87-92 302 (5.0L) or 351W (5.8L): you have a 2G alternator.

This is an early serpentine style. This can only be replaced with a Pivot Mount w/ 7.00” ear spacing alternator. Minor bracket clearancing will be required.

This can be found in the following cars:

93-99 narrow-eared non-DOHC Taurus

94-95 V8 Mustang

94-00 V6 Mustang

94-97 V6 T-Bird/Cougar

95-98 Windstar

91-94 V6 Lincoln Continental.

The early serpentine car and truck alts on Ryan's site are interchangable but the plug and charge stud are clocked differently to fit the wiring to the bracket better. The Pivot Mount w/ 7.00” ear spacing can be swapped into:

1987-1992 Broncos/E-Series/F-series

1966-1995 Mustangs

Other vehicles that use a 7.00” wide Pivot mount alternator

If you have a 93-96 302 (5.0L) or 351W (5.8L): you have a Side Mount 3G already but a 95 amp one. You DO NOT need to get a wiring harness, as since you already have a 3G, it's plug and play!!! I strongly urge you to get a larger charge cable and megafuse though.

For a 130 amp, you can get that for a:

93-96 V8 Econoline with Rear Air Conditioning or the High Output Alternator options

97-03 V6 Econoline E-Series or F-150

95-01 4.0 V6 Explorer or Ranger

at your local parts house for less than eBay.

You'll need the one for late serp. vehicles.

The Side Mount can be swapped into:

1993-1997 5.0L, 5.8L & 7.5L Bronco/F-Series/E-Series

Other vehicles that use a Side Mount alternator

Or you could try to find one like that at a junkyard.

A Note On Belt Squeal: Some 3G alternators create an extra large load on the belt upon engine startup. There is a later part number soft-start regulator that you can be on the look out for. Read more about this here. Thanks to Fodder, SRWillis, and silver70 for the heads up.

Plug Clocking: Each style may have the rear plugs clocked 3 different ways to fit their various vehicles better. They will still fit no matter the clocking but you can remove the case bolts, and reclock the rear to get your optimum position.

Wiring Harness and Charge Cables: The wiring is very simple. I prefer to grab the harness off of certain donor vehicles and then modifying them if they are in great condition. 94-95 Mustang GT's are my favorite as the charge cable is a great length. Many harnesses are available online if you can't find one that suits your needs.

When you swap to a 130 or higher amp 3G, although you do not NEED a larger charge cable such as a 2 Gauge, it is a great idea. Smaller wires/cables cannot always handle such a load and they tend to heat up, some to the point of melting the wire and could start a fire. ALWAYS make sure you use a megafuse rated at least 15-25 amps above your alternator amperage.

Pulleys: For pulleys, you can either re-use your old one, which sometimes you may need a very small washer to use as a spacer if it rubs in the 3G case at all, or you can get a different sized one. It all depends on your needs. A smaller pulley will spin the alternator faster at idle to create maximum output. A larger pulley will allow the engine to rev higher without driving the alternator to fast. Large 3G alternators are safe to ~15,000RPM max. Again, Alt RPM = Engine RPM x Crank Pulley Diameter ÷ Alt Pulley Diameter.

Factory Carb Users: If you have a Factory Ford carburetor (Holley model 4180) with a wire that connects directly to your 1G alt to your electric choke, get a 12 volt electric choke for a Holley 4160, P/N 45-223, and swap it out. Then wire the new choke to 12 volts with key on.

This post will continually be edited as information pops up. Please post any errors you find so this can be THE thread for 3G interchange information.