This thread wont have much tech in it per se, but will have various designs of sliders. Started the thread cause i am building mine now, been researching, and there wasnt a single consolidated thread. Ill post mine up when I am done

Post up yours and Add tech if you want/can guys.

Is this guy still around?

Post up yours and Add tech if you want/can guys.

Is this guy still around?

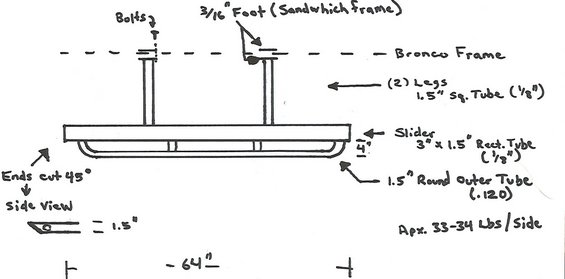

glennd_05 said: