currently swapping in a 06 Superduty D60. but im kinda at a standstill. i need to do something about radius arms. i kinda see it as 4 options. but i am a cheap bastard and price is a huge factor.

my main choice was to be fabricate some custom RA brackets from plate steal. the issue is only steel is kinda expensive and i dont have any time to actually go to a supplier to get it. yet alone fabricating takes alot of time. i imagine i should use 1/4" thick tho i could probably use 3/16", and id probably get a 48x48 sheet so i have plenty for other projects. no idea what it cost but id suspect between 150-300 bucks. then i actually have to fabricate them and buy bolts to mount them. also an issue with these axles are they are at an awkward 3" wider than the frame so id build them to offset them some to remove the 'pinching in' issue.

i could buy some aftermarket brackets for SD axle swaps in out trucks. but these are expensive. and only one actually deals with the issue of the 'pinching in' by angling them. these Sky brackets are $400

www.skysoffroaddesign.com

even the RYD brackets dont seem to deal with that but cost $450

www.skysoffroaddesign.com

even the RYD brackets dont seem to deal with that but cost $450

www.rydmotorsports.com

www.rydmotorsports.com

i am thinknig that if this pinching in issue is not that bad, i could just try and find some junkyard Superduty 2WD brackets. they seem to be pretty common from junkyards unlike the 4x4 trucks, last trip i went i counted 3-4 2wd Superduty. also they bolt on instead of being riveted. I THINK they should still hold a 4x4 RA arm tho im really not that sure. they look pretty sturdy and easy to grab. probably dirt cheap also. but idk how i would take care of the pinching in issue otherwise with them

![Image]()

i think most people are going to say that doing heim joint arms is probably the best way to go. then i can control caster and its probably alot stronger than the stock SD radius arms. also it helps deal with the 'pinching in' factor. but is the most expensive. think that Ruffstuff has the cheapest kit for it being $865 plus $100 shipping. but thats still alot of money when i still havent addressed steering or rear suspension yet

www.ruffstuffspecialties.com

www.ruffstuffspecialties.com

![Image]()

i know an issue with the stock RA arms would be caster. i sorta had a plan for that. my idea was to just redrill the upper mounting hole in the arm for the correct caster. might just need to cut some out of top since it will sit further in on the axle. i would probably weld a Grade 8 washer around the hole to give it support being close to the original hole. behold my mad Paint skills to kinda explain it

![Image]()

my main choice was to be fabricate some custom RA brackets from plate steal. the issue is only steel is kinda expensive and i dont have any time to actually go to a supplier to get it. yet alone fabricating takes alot of time. i imagine i should use 1/4" thick tho i could probably use 3/16", and id probably get a 48x48 sheet so i have plenty for other projects. no idea what it cost but id suspect between 150-300 bucks. then i actually have to fabricate them and buy bolts to mount them. also an issue with these axles are they are at an awkward 3" wider than the frame so id build them to offset them some to remove the 'pinching in' issue.

i could buy some aftermarket brackets for SD axle swaps in out trucks. but these are expensive. and only one actually deals with the issue of the 'pinching in' by angling them. these Sky brackets are $400

92-97 05+ Coil Spring Swap Radius Arm Brackets

-First bracket of its kind to offset off the frame so you're not pinching in the radius arms 3". -Brackets are engineered to have a 3/16" twist in them to line up with the radius arm. -Designed to fit factory radius arm with 18mm bolt eye -Heavily gusseted to mitigate flexing of the brackets...

www.skysoffroaddesign.com

www.skysoffroaddesign.com

Ford OBS Radius Arm Brackets (05-16 Superduty Swap)

Remove your leaf spring hangers and bolt these in place to use the factory 05-16 Radius Arms or our 3 Links. The front two bolts use the factory leaf spring hanger holes and the others need to be drilled. These are designed to be used with the stock coil springs or a 2-2.5" levelling spring...

www.rydmotorsports.com

www.rydmotorsports.com

i am thinknig that if this pinching in issue is not that bad, i could just try and find some junkyard Superduty 2WD brackets. they seem to be pretty common from junkyards unlike the 4x4 trucks, last trip i went i counted 3-4 2wd Superduty. also they bolt on instead of being riveted. I THINK they should still hold a 4x4 RA arm tho im really not that sure. they look pretty sturdy and easy to grab. probably dirt cheap also. but idk how i would take care of the pinching in issue otherwise with them

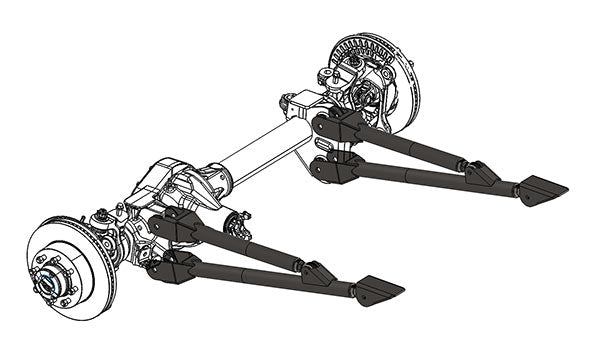

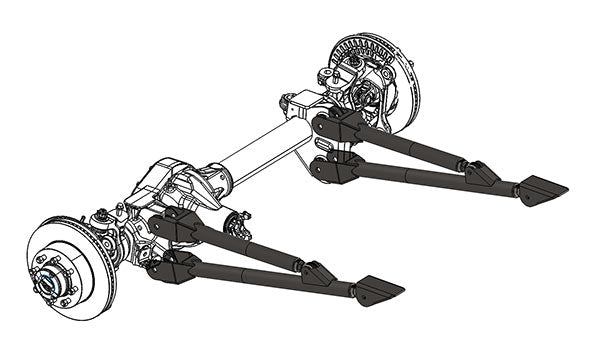

i think most people are going to say that doing heim joint arms is probably the best way to go. then i can control caster and its probably alot stronger than the stock SD radius arms. also it helps deal with the 'pinching in' factor. but is the most expensive. think that Ruffstuff has the cheapest kit for it being $865 plus $100 shipping. but thats still alot of money when i still havent addressed steering or rear suspension yet

Super Duty Dana 60 Front Radius Long Arm Kit 05 Plus

Super Duty Dana 60 Front Radius Long Arm Kit 05 Plus Long arm suspension kit for 2005+ Super Duty Dana 60. This comprehensive long arm kit transforms your Super Duty's front suspension geometry for superior off-road performance and on-road handling. Essential for serious off-road builds where...

i know an issue with the stock RA arms would be caster. i sorta had a plan for that. my idea was to just redrill the upper mounting hole in the arm for the correct caster. might just need to cut some out of top since it will sit further in on the axle. i would probably weld a Grade 8 washer around the hole to give it support being close to the original hole. behold my mad Paint skills to kinda explain it